In the ever-changing landscape of industrial applications, the demand for high-performance materials that can withstand extreme environments has never been higher. Alumina rods, as a cornerstone of advanced technical ceramics, have emerged as a crucial component in various industries, delivering unparalleled performance and durability.

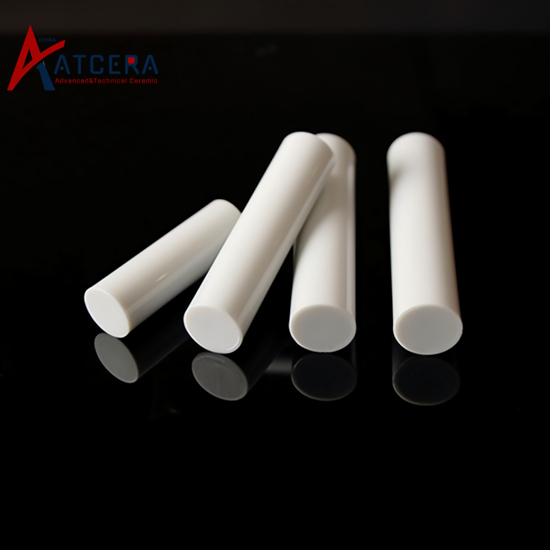

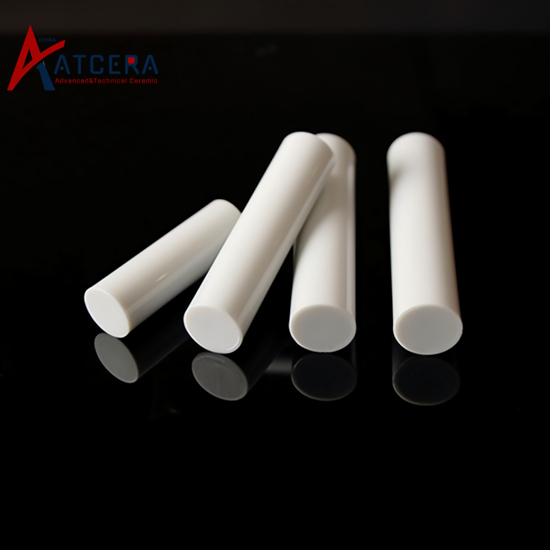

Characteristics of Alumina Rods

Alumina ceramic rods are crafted from high-purity, ultra-fine inorganic compound powders, resulting in a material that possesses exceptional properties. These rods exhibit high temperature resistance, excellent thermal shock resistance, oxidation resistance, and remarkable wear durability. These characteristics enable alumina rods to maintain stable performance under harsh working conditions, making them an ideal choice for a wide range of applications.

Application Fields of Alumina Rods

The versatility of alumina rods is evident in their diverse application fields. In the high-temperature refractory industry, alumina ceramic rods are utilized as furnace roller rods, furnace inlet rods, heat treatment furnace rollers, and heating rods. Their ability to withstand extreme temperatures and resist wear ensures consistent and reliable performance in these demanding environments.

The mechanical engineering industry has also embraced alumina rods due to their high compressive strength, wear resistance, lightweight nature, and stability at high temperatures. These rods are fashioned into hydraulic rods, shafts, plungers, rods, and other mechanical parts, often outperforming traditional metal components in terms of durability and weight reduction.

In the chemical and metallurgical industries, alumina ceramic rods' excellent corrosion resistance and chemical inertness make them suitable for manufacturing various chemical equipment components such as stirring rods, supports, and drainage parts.

How to Select the Right Alumina Rods for Your Project

Choosing the right alumina rods for your specific project is crucial. Factors such as operating temperature, mechanical loads, chemical exposure, and dimensional requirements should be carefully considered. Understanding these parameters and matching them with the appropriate alumina grade and rod dimensions will ensure optimal performance and longevity.

Manufacturing Process of Alumina Rods

The manufacturing process of alumina rods involves precision engineering and stringent quality control. Starting with high-purity raw materials, the powder is formed into rods through advanced molding techniques. These rods then undergo rigorous sintering and post-processing steps to achieve the desired physical and chemical properties. The result is a precision-engineered alumina rod that meets the strictest performance standards.

Case Studies and Success Stories of Using Alumina Rods

Çok sayıda vaka çalışması ve başarı öyküsü, alümina çubukların çeşitli uygulamalardaki etkinliğini vurgulamaktadır. Refrakter endüstrisindeki ısıl işlem fırınlarının verimliliğinin arttırılmasından makine mühendisliği sistemlerindeki bakım maliyetlerinin azaltılmasına kadar, alümina çubuklar çok sayıda gerçek dünya senaryosunda değerlerini kanıtlamıştır.

Çözüm

Gelişmiş teknik seramiklere olan talep artmaya devam ettikçe, alümina çubuklar giderek daha kritik bir rol oynamaya hazırlanıyor. Benzersiz özellikleri ve çok yönlülüğü, farklı endüstrilerdeki çok çeşitli zorlukların üstesinden gelmelerini sağlar. Kuruluşlar, doğru alümina çubukların seçilmesinde ve en son üretim teknolojilerinin kullanılmasında yer alan temel faktörleri anlayarak, benzeri görülmemiş düzeyde performans ve dayanıklılık elde etmek için bu çubuklardan yararlanabilirler.